GLV-11 Solid Steel Roller Shutter Machine Shutter Door Roll Forming Machine

Steel shutters are used to help prevent unauthorized access and vandalism to premises by adding an extra barrier between “outside” and whatever entrances they may be protecting. When open, the shutters provide an almost unobstructed aperture as the shutter and mechanism store above the doorway and out of the way. Furthermore, the doors are tough and have a long life with little maintenance required.

| No. |

Item |

Description |

| 1 |

Coil |

Galvalume, Galvanized |

| 2 |

Raw Material Thickness |

0.6 mm - 1.0 mm |

| 3 |

Working Speed |

30-50 m/min |

| 4 |

Roller Station |

12 Stations |

| 5 |

Dimension (L*W*H)

|

5500 mm*800 mm*1200 mm |

| 6 |

Machine Weight |

4000 KG |

| 7 |

Electrical Control System

|

PLC (can be customized)

|

| 8 |

Drive Motor Power

|

5 KW |

| 9 |

Hydraulic Station Power

|

5 KW |

| 10 |

Power Supply

|

380V, 60HZ, 3 PHASES(can be customized)

|

| 11 |

Cutting Accuracy

|

± 1 mm

|

| 12 |

Driving Mode

|

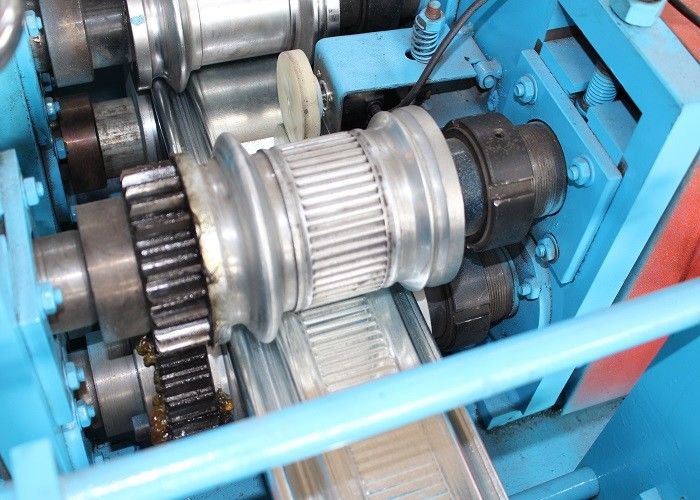

Gear Wheel

|

| 13 |

Material of Shaft

|

60 mm 45#steel forged

|

| 14 |

Material of Roller |

45# Steel Finish Machining, Plated Hard

|

Components and Technical Specification

Manual Uncoiler

It is used to support the steel coil and realize the uncoiling by means of rotatory movement. The steel coil is uncoiled manually. The capacity of this uncoiler is 8 Ton, and it is capable for most of the cases. This equipment is suitable to process the steel coils with 508mm of ID.

Feeding Table

Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

Main Roll Forming Machine

Material of rollers:45# steel,roller surfaces polishing, hard plating , The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Hydraulic System

Power:4kw,Hydraulic oil: 40#

hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

Computer Control Cabinet

The target piece`s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use

PLC:Delta

Shearing Mechanism

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.Material of blades: Cr12,quenching treatment.

Output Table

It adopts welded & screw steel and supported roller to transmit the products,which is used to collect the finished products.

Guarantee

1. Guaranteed against malfunctions due to manufacturing defects for1 years after date of purchase except Electrical parts.

2. Repairs will not be performed even during the guarantee period in the follow circumstances

- Damage occurs due to a natural disaster

- Malfunction occurs due to user error

- Malfunction occurs due to modifications

- Malfunction occurs due to further movement or shipment after installation

Payment terms

40% in advance as down payment

60% is paid before the shipment is processed

Delivery

FOB: Tianjin Xingang Port

The Delivery Time: 30 days after the down payment is received.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!